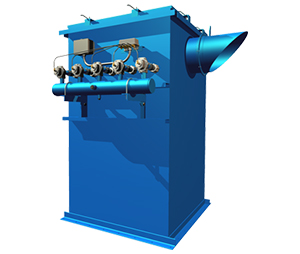

For applications requiring 59 to 1033 ft2 of cloth area per unit with 21″, 41″, 56″ long filters.

Schust™ LIBERATOR PVR Roof Access Baghouse bin vent bring pleated filter technology to container venting and dust recovery.

LIBERATOR PVR Roof Access Baghouse bin vent provide additional filter surface area in a compact design for high efficient applications involving storage bins, silos, or conveyor transfer points.

Additional Extended Features

- Roof Access Baghouse ships completely assembled for rapid installation.

- Units install directly on bins and silos via the supplied flanged inlet. Ductwork is eliminated and installation expenses reduced.

- Low compressed air requirements save energy costs.

- Welded all steel construction provides long-term reliability with minimum maintenance requirements.

- Compact, advanced pleated design provides increased filtering capacity for high efficiency application flexibility.

- Economical solution to meet ever-increasing regulatory requirements.

- Filters are changed from the clean side of the collector housing. Operators are not in direct contact with toxic or valuable collected product. Fugitive emissions associated with dirty side change-outs (typical cartridge collector) are significantly reduced.

- Operating temperatures to 225° F.

Comes Complete With

- Spun Bond Polyester filters featuring a high-flow orifice which develops 30% more cleaning energy.

- Diaphragm pulse valves and compressed air manifold system with NEMA 4 solenoid pilot valve enclosures.

- Programmable solid-state timer controls in a NEMA 4 enclosure. Pre-wired and set-up for continuous cleaning.

- Primed and painted with industrial grade enamel.

- Flanged inlet with safety mesh.

Operating Requirements:

- 115 VAC, 60 Hz. single phase current required for sequence timer

- 90 to 100 PSIG clean, dry, uncontaminated compressed air supply.